Mormally, Lifting capacity of magnet may be influenced by the following factors:

1. Material of parts: Low cabon steel have the best magnetic permeability approach 100%, then moderate carbon steel, high carbon steel. While cast iron have only 70% magnetic conductivity.

2. Air gap: the air gap between parts and magnet will surely reduce the lifting capacity. The more gaps exist, the less holding power on the parts.

3. Thickness of parts: If the parts too thin for the magnet, the magnetic holding force will be wasted and not enough power for lifting.

4. Surface condition of parts: When magnets have the best contact surface with the parts, it will create the most powerful lifting capacity. That means, holding force will reduce because of iron rust, pits and bulges…

Pole extension could pretect magnetic chuck from wearing out and make the working life longer. Besides, for various applications, we have different solution with the option supply of different height and sharp pole extensions.

The high performance epoxy resin filled in poles gaps could protect the chuck surface from coolant oil or water.

| Model | Length (mm) | Width (mm) | Height (mm) | Weight (kg) | Rated load (kg) |

|---|---|---|---|---|---|

| PML-100 | 135 | 60 | 65 | 3.5 | 100 |

| PML-300 | 203 | 87 | 89 | 10 | 300 |

| PML-600 | 266 | 112 | 109 | 21 | 600 |

| PML-1000 | 330 | 148 | 125 | 40 | 1000 |

| PML-1500 | 385 | 178 | 145 | 65 | 1500 |

| PML-2000 | 470 | 178 | 145 | 83 | 2000 |

3.5 times the recommended lifting load

Safe and convenient, with a switch handle security button, one-handed operation can be realized

Without electricity

Magnetic holding force is almost timeless

Made by high-performance magnetic materials(NdFeB)

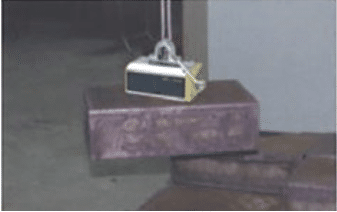

Lifting ferrous/steel plates, blocks and round steel bars

Standard Accessories—

1 set of lifting magnet

Instruction manual

Quality report

Option accessories—

Customized design