As one of the most efficiency workholding tools for metal parts/workpieces, Jumper Magnetics’ prouducts are widely used in metal cutting industry.

Considering to traditional clamping tools, Permanent electromagnetic chucks & Permanent magnetic chucks have the advantage of high working efficiency, high accurancy, 5 side machining available at one single set-up, more convenient to operate, reduced consumption of clamping tools… The holding force up to 16kg/cm2 is powerful enough to hold various sharps iron parts with the help of pole extensions.

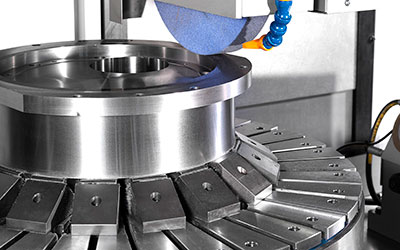

Milling process: The PEM50, PEM75, PPM magnetic chucks are best suitable for milling process, while SPEM magnetic chucks have a full steel structure, which could ensure a better waterproof properties and longer service life. HPEM magnetic chuck combines 2pcs/4pcs of Permanent electro-magnetic chucks with a stand steel base(for installation). It could be used for horizontal machining.

Turning process: High speed rotary of lathe machine makes clamping very complex. Customers should take less deformation, high working efficiency, clamping force, easy operation, less consumption into consideration. Whild our LPEM , CPEM , MPM, GPM, RPM magnetic chucks could satisfy above factors at the same time. Various poles layout could customized due to the sharp of workpieces.

Grinding process: The FPM, and other magnetic chucks could be used for grinding process. Up to 8kg/cm2 holding force could stop parts from sliding and releasing. An hexagon wrench switch MAG and DEMAG phase of the work-table.

Demagnetization: Normally, iron scrap will hold by workpiece due to residual magnetism of magnetic chucks. How to remove these iron scrap is a very big problem for some customers. That’s why we need demagnetizer. The inside electric current will creat a reverse magnetism to remove residual magnetism from scraps and parts. And then they could be easily blow off by compressed air. Demagnetizer always comes with an automation line. The rollers helps parts pass through the central hole.

Engraving & Drilling process: Magnetic workholding could also been applied in Engraving cnc machine. The high accurancy and less deformation makes it one of the best choose for precision engraving and drilling process.

If you want to find a clamping solution for your special metal cutting process, you could also contact us by: sales@jumpermagnetics.com. Or you could leave us a message in below form, you may get response within 24h.